T: +86-18962109320

E: james@sz-welden.com

E: james@sz-welden.com

55 Puxing Road, Linhu Town, Wuzhong District, Suzhou, Jiangsu Province, 215105, China

Views: 0 Author: Site Editor Publish Time: 2025-12-29 Origin: Site

Which is better: CNC Machining or 3D printing? This question has been a topic of debate in the manufacturing world. As both technologies evolve, they offer unique benefits for creating parts.

In this article, we’ll compare CNC machining and 3D printing, focusing on their strengths and weaknesses. You'll learn how to choose the right method based on your project’s needs.

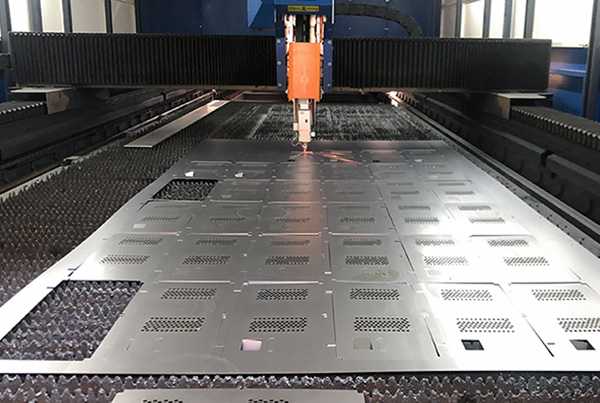

CNC machining (Computer Numerical Control) is a subtractive manufacturing process, meaning it creates parts by removing material from a solid block, or "blank." This material removal is done using various tools, such as lathes, mills, and drills, all of which are controlled by computer programs. The precise control of these tools allows for extremely accurate and repeatable results, making CNC machining suitable for a variety of materials, from metals and plastics to composites.

The process begins by placing a material block into a CNC machine, where it is shaped into a specific part through the use of cutting tools that remove material in precise, programmed steps. Because CNC machining uses rigid tools and control systems, it is known for its high precision and tight tolerances, which makes it ideal for manufacturing parts that require a high degree of accuracy.

Key Advantage: CNC machining excels in producing parts with high precision and tight tolerances. This makes it ideal for applications where dimensional accuracy and smooth surface finishes are critical.

Key Limitation: The biggest drawback of CNC machining is its material waste. Because it removes material from a larger block, there is often significant material waste, especially when working with expensive or hard-to-machine materials. Additionally, the process can be time-consuming, particularly for complex geometries, since multiple steps and tool changes may be required.

3D printing, or additive manufacturing, is a different type of manufacturing technology that builds parts layer by layer from a digital model. Unlike CNC machining, which subtracts material from a larger piece, 3D printing adds material where needed. This process is ideal for creating intricate designs, complex geometries, and prototypes quickly and with minimal setup.

The process starts with a 3D model of the desired part, which is then converted into a file format that the printer can read. The printer uses this file to deposit material, layer by layer, until the part is fully formed. Depending on the printing method (such as FDM, SLS, or SLA), various materials, including plastics, metals, and resins, can be used.

Key Advantage: 3D printing offers significant design freedom. It allows the creation of complex parts that would be difficult, if not impossible, to achieve using traditional subtractive methods like CNC machining. This technology is especially beneficial for rapid prototyping, as it can produce functional parts quickly without the need for expensive tooling or molds.

Key Limitation: One of the main drawbacks of 3D printing is the material strength. While the technology has improved over the years, parts made with 3D printing generally have lower material strength compared to those made with CNC machining, especially when the part requires load-bearing capability or is subjected to harsh environmental conditions. Additionally, the surface finish on 3D printed parts often requires post-processing, such as sanding or polishing, to achieve a smooth and aesthetically pleasing surface.

Feature | CNC Machining | 3D Printing |

Manufacturing Type | Subtractive (material removal) | Additive (material addition) |

Precision | High precision and tight tolerances | Varies; can require post-processing |

Material Waste | High material waste | Minimal material waste |

Part Complexity | Limited by tool access and geometry | No restrictions; highly complex geometries possible |

CNC machining is versatile when it comes to materials. It can work with a wide range of metals such as aluminum, steel, and titanium, as well as plastics like ABS, Nylon, and PEEK. Since CNC machining preserves the full properties of the material, the final part retains its original strength and durability.

● Key Advantage: CNC machining provides strong, durable parts with isotropic properties (same mechanical properties in all directions).

● Key Limitation: Some materials may be difficult to machine, and very hard or tough materials may increase tool wear.

3D printing, particularly with technologies like FDM (Fused Deposition Modeling) and SLS (Selective Laser Sintering), supports a wide array of materials, including plastics, resins, and even metals. However, materials like TPU (Thermoplastic Polyurethane), TPE (Thermoplastic Elastomers), and photopolymer resins are unique to 3D printing, offering flexibility and specialization that CNC machining cannot achieve.

● Key Advantage: 3D printing can handle flexible and composite materials, offering versatility for designs that require specific properties.

● Key Limitation: Many 3D printed parts have anisotropic properties, meaning they are weaker along certain axis lines compared to the surrounding material.

The choice of material significantly impacts the performance of the final part. For CNC machining, the material’s strength, thermal stability, and ability to withstand mechanical stress are fully preserved, making it ideal for parts that need to endure harsh environments. In contrast, 3D printing offers more flexibility in design but may struggle with load-bearing applications or parts that need precise mechanical properties.

Material | CNC Machining | 3D Printing |

Metals | Strong, durable, and high mechanical properties (e.g., aluminum, titanium) | Limited material choices for metals, lower mechanical strength in some cases |

Plastics | Works with a wide range of engineering plastics (e.g., ABS, PEEK) | Suitable for various plastics but may have anisotropic properties |

Flexibility | Less flexible; rigid design | Flexible materials like TPU are easier to print |

Strength | Strong parts with isotropic properties | Weaker parts due to layer adhesion, may require hybrid production |

3D printing is highly effective for low-volume production and customization. Since it requires no tooling and has minimal setup time, 3D printing allows businesses to produce small batches or unique, custom parts with lower upfront costs. For example, a prototype or specialized tool can be printed and ready for use within a day.

● Example: Prototyping complex parts for automotive or medical devices can be done faster and cheaper with 3D printing.

In contrast, CNC machining excels in high-volume production. As setup costs are amortized over a larger number of units, CNC machining becomes more cost-effective in these scenarios. CNC also offers better repeatability and consistency, which is crucial for mass production.

● Example: Manufacturing precision components for the aerospace industry benefits from CNC machining’s ability to handle large volumes without compromising quality.

For parts with intricate, freeform geometries, 3D printing has the upper hand. Unlike CNC machining, which is constrained by tool access and geometry, 3D printing allows for the creation of complex internal structures, organic shapes, and geometries that would be impossible to machine using traditional methods.

Feature | CNC Machining | 3D Printing |

Tool Accessibility | Limited by cutting tool geometry and part design | No tool access restrictions; complex shapes possible |

Internal Features | Hard to produce internal geometries, requires extra machining | Easily create hollow structures, lattices, and internal channels |

Shape Complexity | Limited by machining constraints | Ideal for highly intricate, organic geometries |

CNC machining is well known for its high precision, capable of achieving tolerances as tight as ±0.005mm. Additionally, CNC can produce smooth surface finishes directly from the machine, often requiring little post-processing. This makes it the ideal choice for parts that need to meet strict dimensional requirements and fit precisely with other components.

● Example: Aerospace components that require tight tolerances and smooth surfaces benefit from CNC machining.

3D printing, while offering excellent design freedom, often requires post-processing for precision and surface finish. The precision of 3D printing varies based on the technology used, but parts typically have visible layer lines, especially when using FDM printers. This can be mitigated with sanding, polishing, or other finishing methods.

Feature | CNC Machining | 3D Printing |

Precision | High precision, typically ±0.005mm | Varies by process, can require post-processing |

Surface Finish | Smooth finish, minimal post-processing | Visible layer lines, requires finishing for smoothness |

Post-Processing | Typically minimal, may include polishing | Requires sanding, polishing, or other methods |

While CNC machining has higher upfront costs due to setup, programming, and tooling, it becomes cost-effective for medium to high-volume production. The cost per part decreases as the production volume increases, making it ideal for manufacturing hundreds or thousands of parts.

● Example: Producing parts in high volumes for consumer electronics or automotive applications can justify the initial cost of CNC machining.

For 3D printing, the cost per part remains consistent regardless of volume, making it cost-effective for low-volume runs or one-off parts. However, it may not be as cost-effective for larger production runs compared to CNC machining.

Feature | CNC Machining | 3D Printing |

Setup Costs | High, requires tooling and programming | Minimal, no tooling required |

Cost per Unit | Decreases with volume | Remains consistent regardless of volume |

Volume Efficiency | Becomes more cost-effective at high volumes | Best for low-volume runs, prototyping |

CNC machining is ideal for high-precision, large-volume production. However, 3D printing offers faster lead times and quicker setup, especially for rapid prototyping or small batches. Both technologies have their strengths in terms of speed and efficiency, depending on the production scale.

Feature | CNC Machining | 3D Printing |

Lead Time | Longer setup, faster cutting for large runs | Quick setup, slower build time for larger parts |

Volume Scalability | Best for medium to large volumes | Best for small batches and prototypes |

Setup Time | Significant, requires programming and tooling | Minimal, no tooling required |

CNC machining generates more material waste because it cuts away excess material from a solid block. This waste, while often recyclable, contributes to a higher material cost and environmental footprint.

One of the main advantages of 3D printing is its low material waste. Since material is added layer by layer, there is minimal waste produced, making it more environmentally friendly compared to traditional subtractive methods like CNC machining.

Feature | CNC Machining | 3D Printing |

Material Waste | High, due to subtractive process | Low, additive process generates less waste |

Energy Consumption | High due to extended machining time | Generally lower due to faster setup and processing times |

Environmental Impact | Higher material usage and waste | More eco-friendly due to less material waste |

Choosing between CNC Machining and 3D Printing depends on factors like part complexity, production volume, and budget. For high-precision, large-volume production, CNC machining is ideal. For rapid prototyping and low-volume runs, 3D printing excels. As both technologies evolve, they may complement each other in the future.

At Suzhou Welden Intelligent Tech Co., Ltd., their advanced solutions combine the best of both worlds, offering high-quality manufacturing that meets diverse production needs.

A: CNC Machining is a subtractive manufacturing process that removes material from a block to create parts, while 3D Printing is an additive process that builds parts layer by layer from a digital model.

A: CNC Machining is ideal for high-precision parts and large-volume production, whereas 3D Printing is better for rapid prototyping and creating complex geometries.

A: Yes, CNC Machining can be used for low-volume production, but it becomes more cost-effective as the production volume increases due to setup costs being spread over more units.

A: 3D Printing excels in producing custom, complex parts with intricate designs quickly and at a lower cost for small batches compared to CNC Machining.

A: CNC Machining is more cost-effective for high-volume production, while 3D Printing is more affordable for low-volume runs or rapid prototyping.

A: CNC Machining offers high precision and the ability to produce strong, durable metal parts with excellent surface finishes, making it ideal for metal components.