T: +86-18962109320

E: james@sz-welden.com

E: james@sz-welden.com

55 Puxing Road, Linhu Town, Wuzhong District, Suzhou, Jiangsu Province, 215105, China

Views: 0 Author: Site Editor Publish Time: 2025-02-25 Origin: Site

Precision sheet metal parts are the backbone of modern manufacturing, playing a vital role in enhancing product quality, performance, and production efficiency across diverse industries. Designed with strict accuracy and reliability in mind, these components ensure that products not only fit perfectly but also withstand demanding conditions. From automotive and aerospace to electronics and medical devices, precision sheet metal fabrication is essential for achieving consistent, high-quality results.

In this article, we will explore the benefits of precision sheet metal parts, focusing on their impact on product quality and efficiency, and highlight how Welden – Smart and Precision Manufacturing delivers value as a trusted partner in this field.

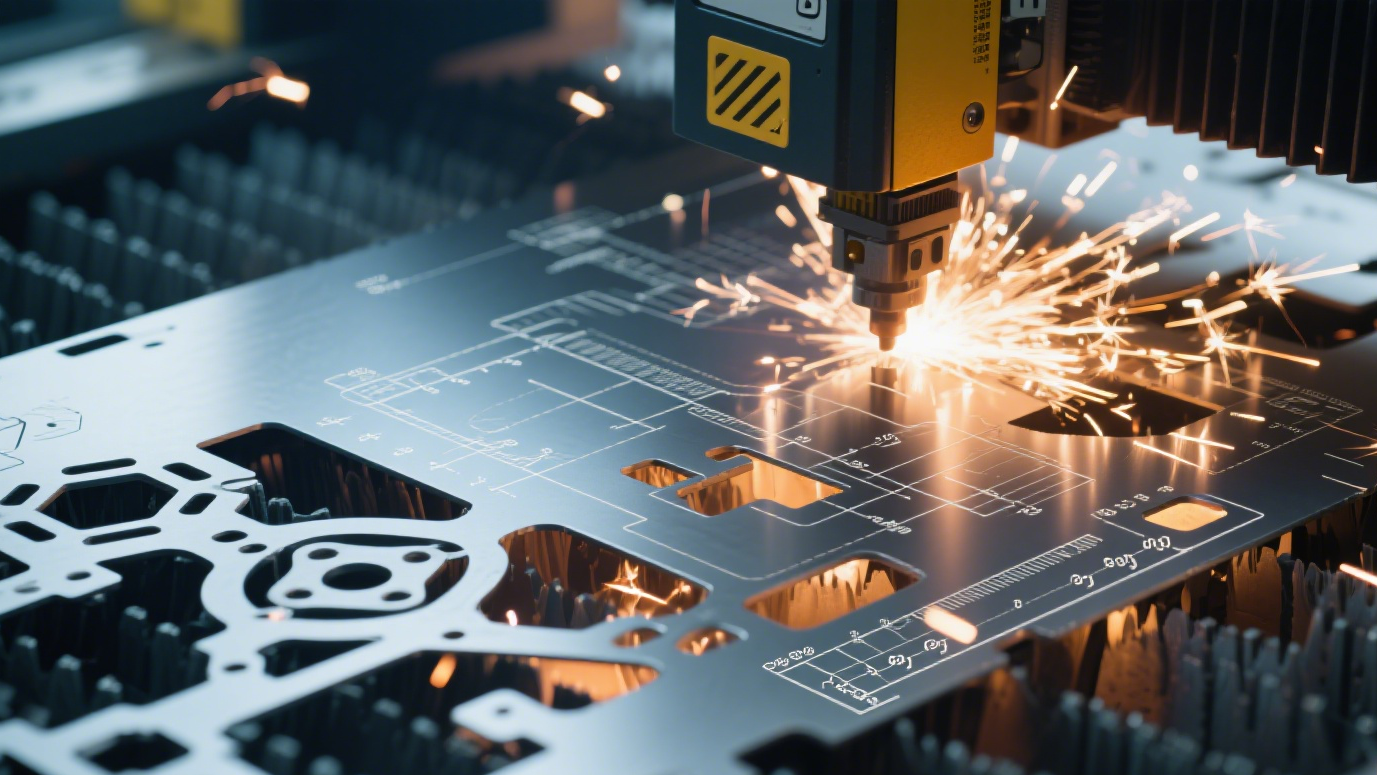

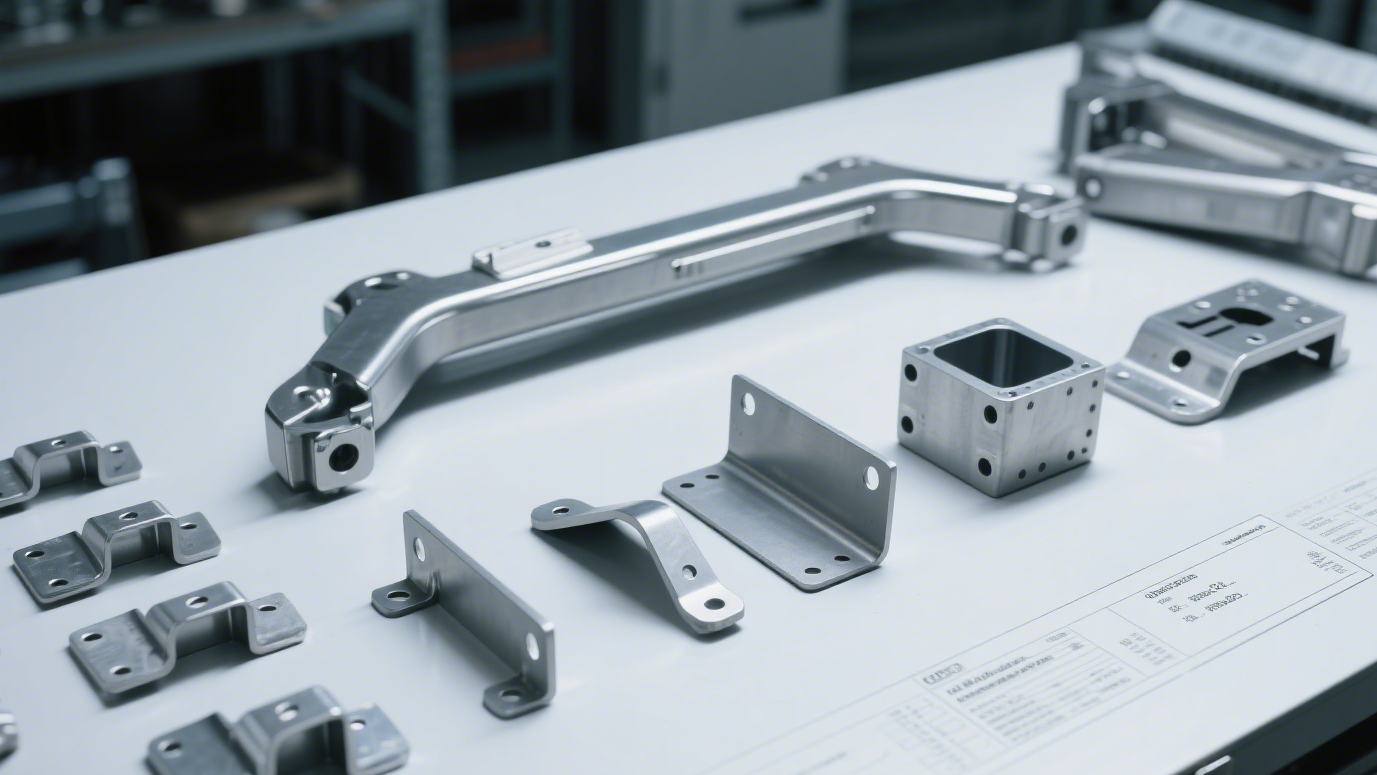

Precision sheet metal parts are components manufactured from flat sheets of metal using processes such as laser cutting, CNC machining, stamping, bending, and welding. These advanced techniques enable manufacturers to create parts with tight tolerances and complex geometries.

Automotive: chassis parts, brackets, housings, body panels

Aerospace: fuselage panels, structural supports, interior components

Electronics: enclosures, casings, and protective frames

Medical devices: surgical equipment, housings, and support structures

Consumer goods: durable and reliable product parts

By meeting rigorous industry requirements, precision sheet metal fabrication ensures durability, functionality, and safety in high-demand applications.

One of the primary benefits of precision sheet metal parts is the accuracy they bring to the manufacturing process. When parts are manufactured with precise measurements, the final product performs as expected, with little to no variation. This ensures a higher level of consistency across production runs and minimizes errors.

In the automotive industry, for example, precision sheet metal parts are crucial for ensuring that components like brackets, housings, and engine parts fit together seamlessly. This level of accuracy reduces the chances of defects, resulting in better vehicle performance and reliability. The precision involved also minimizes the need for additional adjustments or fixes during the assembly process, which can be time-consuming and costly.

Precision sheet metal parts are often made from high-quality materials like stainless steel, aluminum, and other alloys that offer exceptional durability. These materials are selected to withstand harsh environments, resist corrosion, and endure prolonged use.

In aerospace, precision sheet metal parts must meet stringent standards for safety and performance. Components such as fuselage panels and structural supports are subjected to high levels of stress, so the durability of these parts is paramount. When precision sheet metal parts are used, the resulting product is not only reliable but also longer-lasting, minimizing the risk of failure in the field.

Reliability is another key factor when it comes to product quality. Precision manufacturing ensures that parts are made to exact specifications, reducing the likelihood of malfunctions, wear and tear, and premature failure. This is particularly important in high-performance industries like medical devices and electronics, where precision and reliability are non-negotiable.

By using precision sheet metal parts, manufacturers can guarantee that their products meet the highest standards of performance. Whether it’s in a medical device used for life-saving procedures or in a consumer electronic device that requires uninterrupted operation, precision sheet metal ensures that the product will operate as intended, even under the most demanding conditions.

Precision sheet metal parts contribute significantly to shorter production cycles. Advanced technologies like laser cutting, CNC machining, and automated bending allow for high-speed, high-accuracy production. These methods enable manufacturers to produce parts faster while maintaining tight tolerances.

Welden - Smart and Precision Manufacturing is committed to providing efficient and streamlined production processes. Our use of advanced technologies reduces the time spent on each part, allowing for quicker turnarounds and lower production costs. This efficiency is particularly important when dealing with large-volume orders, where delays can lead to significant losses.

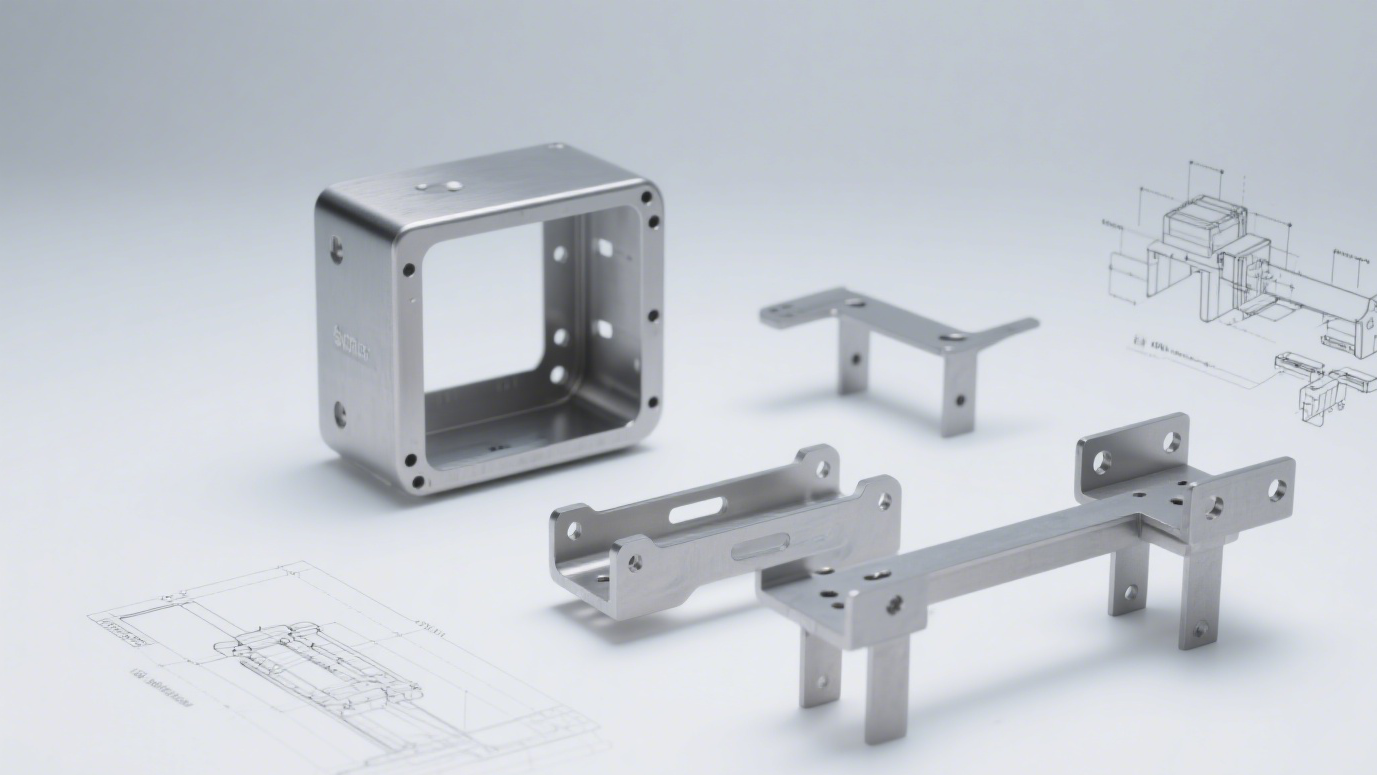

With precision sheet metal parts, manufacturers can achieve a high level of repeatability in production. Once a part design is finalized, the same part can be produced consistently with minimal variation. This is particularly important for industries that rely on large-scale production runs, such as automotive manufacturing.

For example, Welden specializes in high-volume production where every part must meet the same exact standards. Our precision processes ensure that each part in a batch is identical, which reduces the chance of assembly errors and the need for costly rework.

One of the key advantages of precision sheet metal fabrication is the efficient use of materials. With technologies like laser cutting, there is minimal waste, as the cuts are made with extreme precision. This not only reduces the material costs but also contributes to a more sustainable manufacturing process by reducing scrap and waste.

At Welden, our advanced manufacturing techniques allow us to maximize material utilization, ensuring that our clients receive high-quality parts at competitive prices. By minimizing waste, we help our customers lower costs and improve the sustainability of their operations.

While the initial investment in precision manufacturing equipment may be higher, the long-term cost savings are significant. Precision sheet metal parts help reduce waste, decrease production time, and improve the overall efficiency of the manufacturing process.

Lower Scrap Rates: Precision techniques such as laser cutting and CNC machining generate less scrap material compared to traditional methods. This directly translates to lower material costs for the manufacturer.

Fewer Rework and Adjustments: Precision parts are less likely to require rework or adjustments, saving time and reducing labor costs.

Long-Term Durability: The durability of precision sheet metal parts means that the final product will require fewer replacements and maintenance over its lifespan, resulting in long-term savings.

Welden understands the importance of providing cost-effective solutions to our clients. By offering precision sheet metal parts that are both high-quality and affordable, we help our customers maintain competitive pricing in their respective markets.

At Welden, we leverage state-of-the-art technology and a dedicated team of engineers to produce precision sheet metal parts that meet the highest industry standards. Here’s how we ensure that our customers benefit from improved quality and efficiency:

Cutting-Edge Technology: We use advanced technologies like laser cutting, CNC punching, and automated bending to produce parts with incredible precision. Our facilities are equipped with the latest equipment to ensure that every part is manufactured to the exact specifications.

Strict Quality Control: Quality is at the core of everything we do. Our quality control team inspects every batch of parts to ensure that they meet both our internal standards and customer requirements. Whether it's dimensional accuracy or material strength, we rigorously test each part to guarantee its reliability.

Tailored Solutions: We understand that each customer has unique needs. That's why Welden offers custom solutions to fit specific requirements. From prototyping to mass production, we work closely with clients to ensure their vision is brought to life with precision.

Welden stands out through its multifaceted expertise:

Advanced Welding: Ensuring precision and reliability for busbars and complex geometries.

Precision Stamping: Delivering accurate, repeatable component creation.

Sheet Metal Fabrication: Offering complete manufacturing from blank to final form.

Surface Treatment: Enhancing component durability, appearance, and functional performance.

Precision sheet metal parts are essential for improving both product quality and production efficiency. By providing accurate, durable, and reliable components, they ensure that products meet the highest standards and perform optimally. At the same time, precision sheet metal manufacturing reduces production time, minimizes waste, and lowers costs, making it a valuable investment for manufacturers.

At Welden, we are committed to delivering high-quality precision sheet metal parts that meet the unique needs of our clients. Our advanced technologies, strict quality control processes, and dedication to customer satisfaction make us the ideal partner for businesses looking to improve their products’ quality and efficiency.If you’re ready to take your manufacturing process to the next level, visit our website to learn more about how Welden can support your precision sheet metal needs.