T: +86-18962109320

E: james@sz-welden.com

E: james@sz-welden.com

55 Puxing Road, Linhu Town, Wuzhong District, Suzhou, Jiangsu Province, 215105, China

Views: 0 Author: Site Editor Publish Time: 2025-10-15 Origin: Site

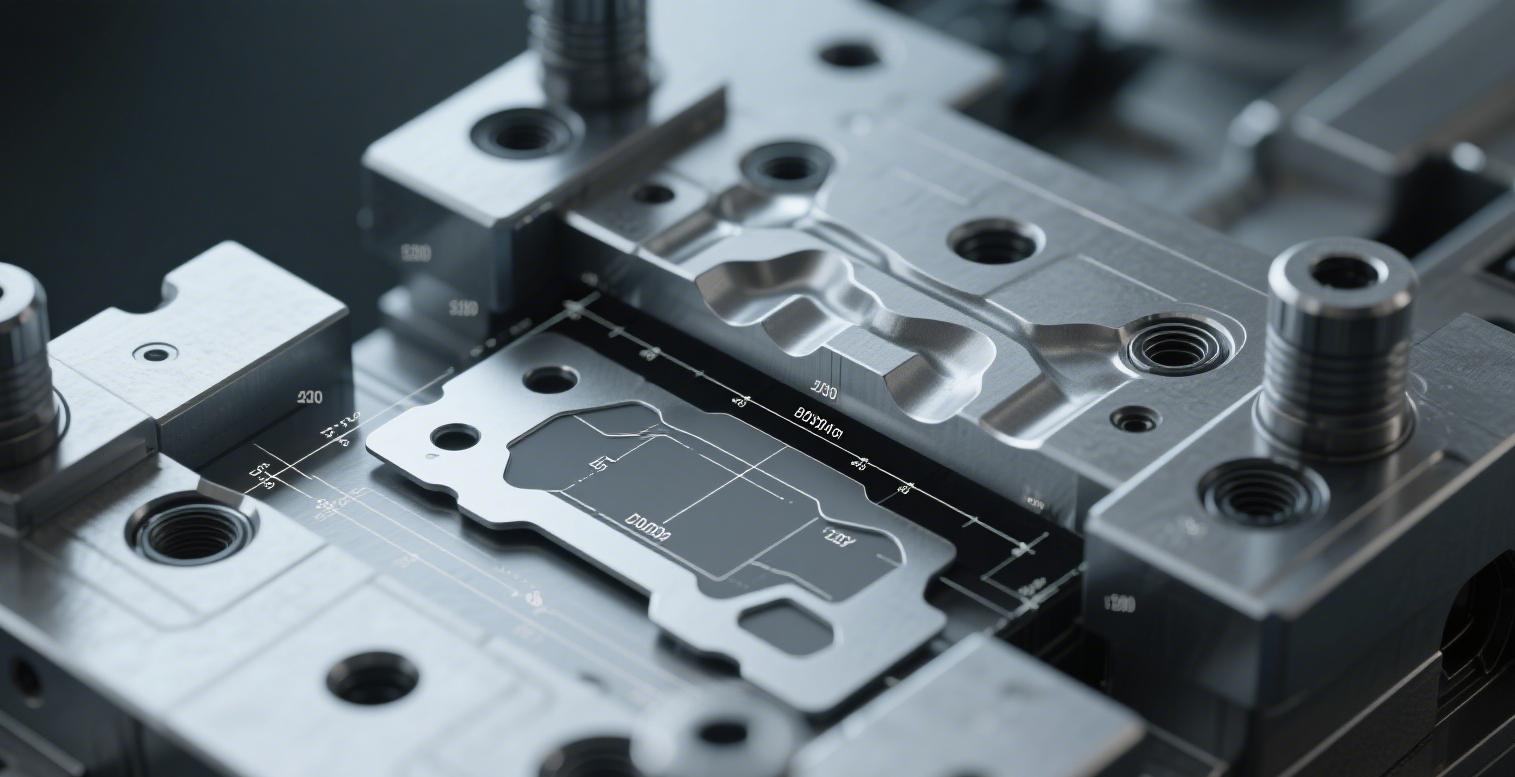

The consumer electronics industry is fast-paced, demanding continuous innovation, rapid production, and consistent product quality. Manufacturers in this sector face mounting pressure to produce complex components while maintaining efficiency and minimizing costs. Precision stamping has emerged as a game-changer in achieving these goals. By offering high-speed production, reduced waste, and improved accuracy, precision stamping is transforming how consumer electronics are manufactured.

The consumer electronics industry requires precision, speed, and reliability in its components, whether it's the latest smartphone, computer, or home appliance. Precision stamping has gained widespread use for its ability to produce high-quality parts quickly and at scale. The technique involves high-speed stamping machines that create intricate shapes and features with tight tolerances, making it ideal for mass-producing consumer electronics components.

Smartphones and tablets are at the forefront of the consumer electronics market, with millions of units sold every year. Precision stamping is used to manufacture components such as the external casing, internal supports, and connectors for these devices. The high precision required ensures the components are durable and meet the tight design tolerances needed for such devices. As a result, smartphones and tablets benefit from lighter, stronger, and aesthetically pleasing parts that fit perfectly and function reliably.

Television sets and display monitors rely on precision-engineered parts for structural integrity and optimal performance. Parts such as metal frames, brackets, and internal supports are produced using precision stamping. These components must align perfectly and provide enough strength to support the weight and stress placed on the devices. Precision stamping offers the necessary accuracy to manufacture these critical parts while maintaining the strength needed for long-lasting functionality.

In the production of desktop computers, laptops, and peripheral devices, precision stamping is indispensable. Components like casings, battery compartments, and connectors require precise manufacturing to ensure they fit together seamlessly. Precision stamping helps achieve this accuracy, enabling manufacturers to create components that meet the high-performance and design standards set by the consumer electronics market.

Precision stamping is also used in the production of home appliances such as microwaves, refrigerators, and washing machines. These devices contain various metal parts, such as casings, fan blades, and structural supports, which require precise manufacturing for both performance and safety. By using precision stamping, manufacturers can create these components more quickly, with minimal waste and reduced production costs.

The use of precision stamping significantly boosts efficiency across various stages of production. From accelerating production speeds to reducing waste and improving quality, this process is a key factor in ensuring that consumer electronics can meet the growing market demands.

In the competitive consumer electronics market, speed is crucial. With technological advancements occurring rapidly, manufacturers need to meet tight deadlines and high volume demands. Precision stamping addresses this challenge by allowing for high-speed production. The automated nature of precision stamping machines ensures that parts can be produced at a much faster rate than traditional manufacturing methods.

Unlike traditional machining or casting, which can be slower and labor-intensive, precision stamping operates in high-volume runs, enabling manufacturers to produce thousands of identical components in a short period. This faster production helps electronics companies bring new products to market quickly and stay ahead of the competition.

One of the most significant benefits of precision stamping is its ability to reduce material waste. In traditional manufacturing methods such as casting or machining, a large percentage of raw materials is often wasted during the production process. In contrast, precision stamping uses advanced techniques to optimize material usage, ensuring minimal scrap and waste.

This reduction in waste is particularly important for consumer electronics, where cost efficiency is paramount. By using raw materials more efficiently, manufacturers can lower production costs, reduce their environmental impact, and maintain a high level of profitability, all while ensuring the components meet the required specifications for quality and performance.

The automation involved in precision stamping reduces the need for manual labor, which, in turn, lowers labor costs. Fewer workers are needed to operate stamping machines, and the machines can run for long periods with minimal human intervention. This automation leads to fewer errors and greater consistency, as the process is tightly controlled by technology rather than dependent on human input.

Precision stamping also reduces the chances of defects or inconsistencies in the parts being produced. Because the stamping process is highly accurate and automated, there is a much lower risk of human error compared to traditional manufacturing methods. This ensures that parts meet the required standards consistently, improving overall product quality.

The ability to quickly adjust designs and tooling in the stamping process offers another efficiency advantage. In traditional manufacturing, changes to product designs often require lengthy retooling, which can be both time-consuming and expensive. Precision stamping, however, allows manufacturers to make quicker adjustments to the tools and molds used in the production process, shortening the time required to implement design changes.

This flexibility helps consumer electronics manufacturers rapidly adapt to shifting market trends and consumer preferences. It also allows them to develop new products more quickly and at lower costs, helping them stay competitive in an industry where product life cycles are constantly shrinking.

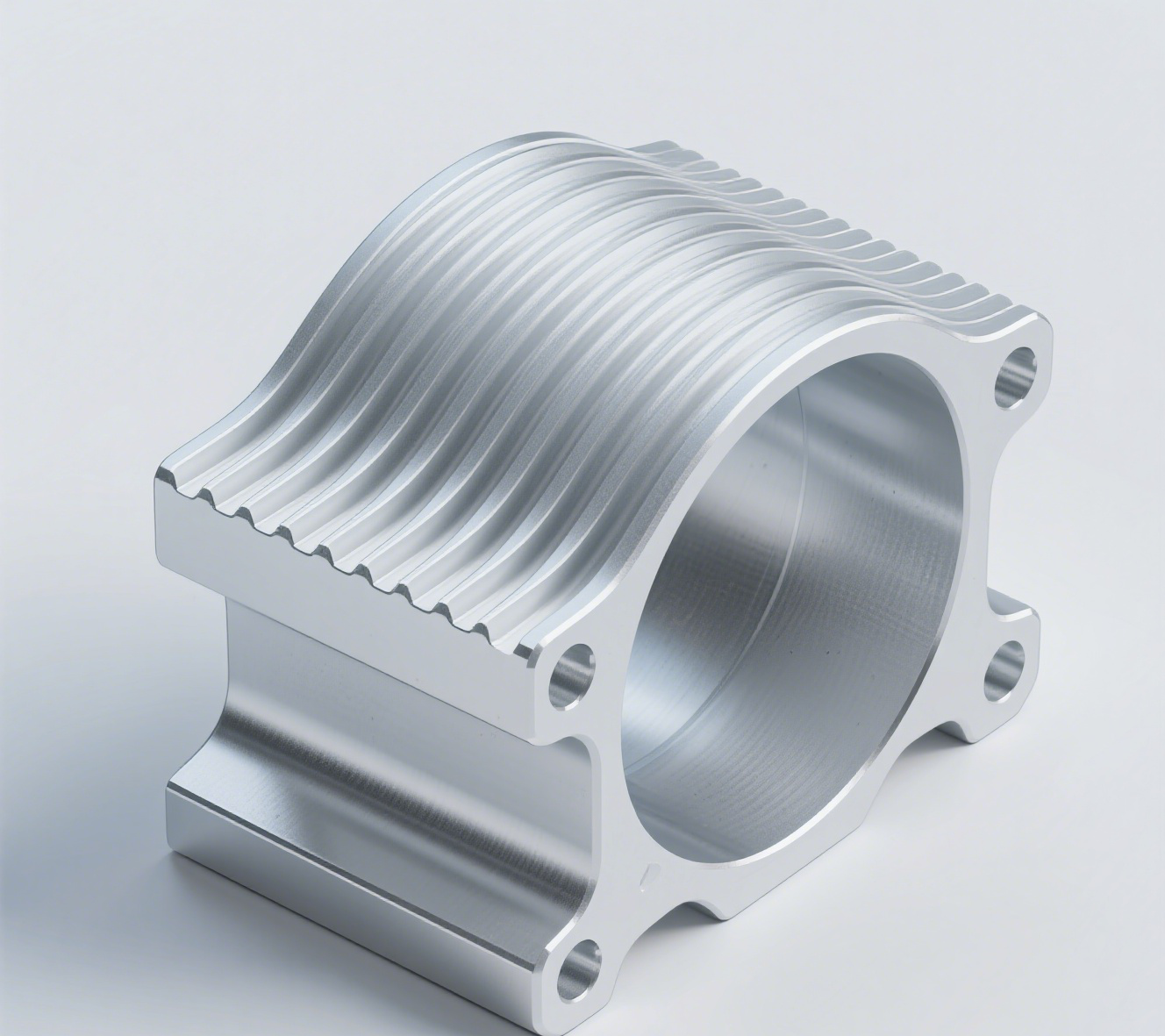

While precision stamping is known for improving manufacturing efficiency, it also plays a vital role in enhancing the quality of consumer electronics components. The accuracy and consistency that precision stamping provides help ensure that each part meets the required specifications, contributing to the overall quality and longevity of the product.

One of the core advantages of precision stamping is the consistency it offers. Every part produced is virtually identical, which is crucial for ensuring that components fit together as intended during assembly. In consumer electronics, even small variations in size or shape can cause alignment issues or result in parts not functioning properly.

Precision stamping ensures that each component is produced with tight tolerances, so manufacturers can rely on the parts to fit perfectly, reducing the risk of defects or performance issues.

In addition to ensuring accuracy, precision stamping also improves the durability of components. The stamped parts are often stronger and more resilient than those produced through other methods, making them ideal for the rigors of everyday use in consumer electronics.

For example, components like metal frames for smartphones or computer casings need to withstand physical stresses, impacts, and wear over time. Precision stamping provides the strength and reliability needed to ensure that these parts can endure the conditions they will face in the real world.

Consumer electronics are becoming more intricate, with complex designs and smaller, more compact components. Precision stamping enables manufacturers to create parts with complex geometries that might be impossible to achieve with traditional methods. This flexibility supports innovation and allows manufacturers to produce parts that meet the demands of modern electronics.

Precision stamping is an invaluable process for improving efficiency in consumer electronics manufacturing. From speeding up production and reducing waste to ensuring high-quality, durable parts, this technology plays a critical role in meeting the growing demands of the industry. As manufacturers continue to innovate and push the boundaries of what’s possible, precision stamping will remain a vital tool in ensuring that components are produced with the highest level of accuracy and efficiency.

At Welden - Smart and Precision Manufacturing, we leverage cutting-edge precision stamping technology to produce high-quality components for the consumer electronics industry. Our commitment to efficiency and precision ensures that we can meet the demands of our clients while maintaining the highest standards of quality. To learn more about our precision stamping services and how they can help your business, visit our website at www.sz-welden.com and explore our wide range of capabilities.