T: +86-18962109320

E: james@sz-welden.com

E: james@sz-welden.com

55 Puxing Road, Linhu Town, Wuzhong District, Suzhou, Jiangsu Province, 215105, China

Views: 0 Author: Site Editor Publish Time: 2025-12-24 Origin: Site

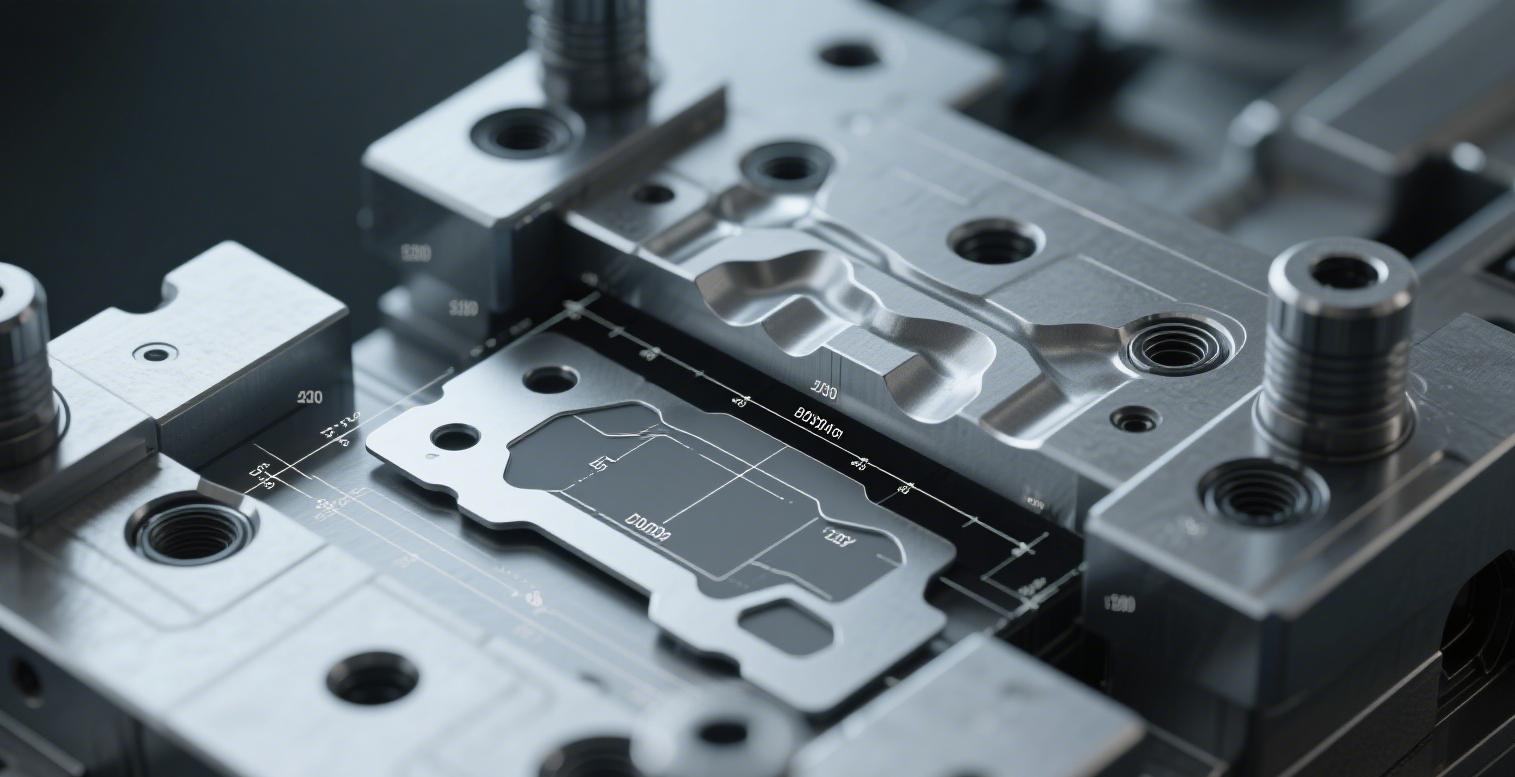

CNC Machining is changing how modern products are built, pushing precision and speed to new levels. This article explains why it has become a strategic technology in today’s manufacturing world and what makes it essential for engineers and buyers. You will see how it reshapes design, production, and large-scale industrial workflows.

CNC Machining has become the foundation of modern precision engineering. As industries push toward higher performance, tighter tolerances, and more complex geometries, CNC technology provides the consistency and control that traditional machining cannot match. The combination of digital programming, real-time monitoring, and intelligent compensation creates a manufacturing environment where accuracy is predictable, repeatable, and scalable. In this section, we explore the key advancements that make CNC the new benchmark for global manufacturing.

Modern CNC systems now reach tolerances as tight as ±0.002 mm, far beyond what manual operators can achieve. This improvement is driven by high-precision linear motors, closed-loop feedback systems, rigid machine structures, and advanced measurement tools.

Industries such as aerospace, robotics, optics, and medical devices rely on these micron-level capabilities to produce components that require flawless surface finishes, precise alignment, and consistent fitment across thousands of units. Precision in these fields is not optional—it directly affects safety, reliability, and functional performance.

Unlike manual machining—where outcomes vary by operator skill—CNC Machining ensures that every part matches the programmed specification. This consistency strengthens product reliability, reduces quality disputes, and builds long-term brand trust for manufacturers.

To demonstrate how CNC tolerances support different industries, the table below outlines typical requirements:

Industry | Typical Required Tolerance | Why CNC Is Ideal |

Aerospace | ±0.005–0.01 mm | Ensures structural integrity and flight safety |

Robotics | ±0.01 mm | Enables smooth movement and stable kinematics |

Optics | ±0.002–0.005 mm | Required for lens housings and alignment frames |

Medical Devices | ±0.01 mm | Critical for implants and surgical tool accuracy |

Across all segments, CNC precision becomes a competitive advantage that directly enhances reliability and downstream performance.

5-axis and 7-axis CNC machines introduce a new level of geometric freedom. They allow the spindle and cutting tools to move simultaneously along multiple planes, enabling manufacturers to produce:

Deep internal cavities

Undercuts and compound angles

Organic or free-form contours

Turbine-grade blades and impellers

These features are nearly impossible to achieve using traditional 3-axis setups without multiple re-fixtures. Multi-axis machining reduces the number of setups required, minimizing human intervention and alignment errors. This not only improves precision but also reduces machining time.

As products become smaller, lighter, and more integrated, multi-axis machining is shifting from a specialized capability to a baseline requirement. In sectors such as aerospace, medical, and electric vehicles, complex shapes are now standard—and multi-axis CNC machines make this complexity affordable and repeatable.

Temperature change is one of the biggest sources of machining error. Modern CNC Machining systems counter this issue using:

Live temperature monitoring

Spindle load sensors

Real-time deformation prediction

Automated thermal compensation algorithms

As the machine heats up during heavy or high-speed operations, it adjusts toolpaths automatically to compensate for thermal expansion. Even microscopic shifts can impact accuracy, but advanced CNC controllers eliminate drift before it becomes a measurable defect.

This technology enables longer production runs, higher speeds, and extended unmanned operation—an ideal setup for mission-critical CNC Parts. Factories gain confidence that the first part and the last part in a batch will match perfectly, regardless of run duration or cutting conditions.

Modern CNC machines handle a broader range of materials than ever before. This versatility gives engineers more room to innovate without trading off manufacturability. Common materials include:

Aerospace-grade aluminum (e.g., 6061, 7075)

Medical stainless steels (304, 316L)

Heat-resistant titanium alloys

High-performance engineering plastics (PEEK, Delrin, nylon)

Carbon composites and hybrid materials

This wide adaptability opens creative freedom for designers developing lightweight structures, thermally stable housings, corrosion-resistant forms, or biocompatible components. CNC Machining becomes the common platform across industries exploring advanced materials and next-generation structures.

Whether the goal is strength, heat resistance, flexibility, or miniaturization, CNC supports nearly any design direction—making it a cornerstone of future manufacturing innovation.

CNC machining drastically shortens time-to-prototype. Engineers can validate designs within days instead of weeks, allowing faster iteration and reducing the risk of late-stage design failure. This speed is critical in consumer electronics, automotive EV components, and hardware startups. The ability to test multiple design variations in rapid cycles becomes a major advantage in competitive markets.

Unlike 3D printing, where prototype properties may differ from production output, CNC prototypes are identical in material strength, surface finish, and tolerances to mass-produced parts. This seamless transition reduces development uncertainty and supports direct-to-production workflows. Businesses benefit by avoiding surprises during scale-up.

CAD design files feed directly into CAM programming, ensuring consistent geometry from digital model to physical part. Simulation tools detect collisions, optimize toolpaths, and reduce machining time before cutting even begins. This digital synergy is crucial for modern R&D teams aiming for speed without compromising precision.

With high cutting speeds and automated tool changing, CNC Machining supports rapid low-volume production and is one of the most efficient solutions for parts needed within tight deadlines. Especially for bridge manufacturing between prototype and mass production, CNC remains the most cost-effective option.

Modern CNC cells support robotic loading, automatic pallet changing, and unattended “lights-out” operation. Manufacturers significantly increase output without expanding manpower, ideal for automotive, medical, and aerospace sectors. Automation also reduces human error, leading to higher overall process reliability.

CNC systems equipped with vibration sensors, tool wear detection, and adaptive feed control minimize errors. Smarter control reduces scrap, lowers material waste, and improves cost predictability. When fewer materials are wasted, overall unit cost decreases, making CNC a financially viable long-term investment.

High-performance coatings, advanced carbide tools, and optimized chip evacuation allow faster cutting speeds and longer tool life. These improvements increase throughput and reduce downtime. As tooling evolves, CNC machining cycles become faster, more stable, and increasingly automated.

CNC Machining aligns naturally with lean strategies by ensuring process standardization, reducing variability, and enabling continuous improvement through data analytics. Factories can track bottlenecks, machining times, and tool wear trends to refine workflows and minimize non-value-added activities.

Digital twins replicate CNC machines virtually, enabling manufacturers to simulate cutting paths, analyze performance, and optimize programming before production. This reduces machine wear and accelerates setup time. Companies using digital twins report fewer collisions, faster prototyping, and improved part quality.

Artificial intelligence analyzes spindle load, tool wear, vibration signals, and machining temperature. AI automatically adjusts speeds and feeds, identifies optimal parameters, and predicts potential failures—leading to smoother cuts and longer tool life. As a result, machining strategies become self-optimizing.

IoT-enabled CNC machines provide real-time dashboards that show utilization, cycle times, energy consumption, and maintenance alerts. These insights help factories enhance productivity and minimize unscheduled downtime. Managers can detect inefficiencies instantly and resolve them before delays occur.

Digital Technology | What It Does | Benefits for Manufacturers | Typical Use Case |

Digital Twins | Virtual replica simulates machining behavior | Cuts setup time, reduces collision risk, improves first-pass yield | Simulating turbine blade machining steps |

AI Toolpath Optimization | AI adjusts feeds, speeds, and tool engagement in real time | Boosts productivity, stabilizes cutting forces, extends tool life | High-speed milling of aluminum housings |

Predictive Maintenance | Analyzes vibration, spindle load, thermal signatures | Prevents downtime, lowers repair cost, increases uptime | Early detection of spindle bearing wear |

IoT Machine Monitoring | Tracks machine utilization and cycle time | Improves scheduling, enables lights-out manufacturing | Automotive precision parts production |

In-Process Measurement | Measures part features while machining | Ensures zero-defect flow and reduces inspection time | Medical implants and micro-components |

By analyzing sensor data, predictive maintenance identifies tool degradation and spindle issues before they cause defects or machine stoppage. This approach maximizes uptime and reduces repair costs. It also makes maintenance scheduling more accurate and less disruptive.

Precise toolpaths and optimized cutting parameters reduce unnecessary material removal. Near-net-shape machining and advanced nesting strategies further improve material utilization. The result is lower cost and reduced environmental impact.

Modern CNC controllers optimize spindle power usage, coolant circulation, and idle consumption. High-efficiency motors reduce energy demands while maintaining precision. This makes CNC one of the most environmentally responsible subtractive technologies.

Predictive maintenance and stable production conditions prolong machine life, reducing the environmental impact of machine replacement and lowering operational costs. More durable machines also improve long-term ROI.

CNC Machining’s ability to handle metals like aluminum and titanium aligns with sustainability goals because these materials can be recycled repeatedly without degradation. This makes CNC a natural choice for closed-loop circular manufacturing.

Complex structural parts, turbine blades, housings, and landing gear components rely on CNC’s high precision and material compatibility. Aerospace demands both strength and lightness—CNC delivers both.

CNC Machining supports battery housings, motor parts, brackets, and drive-train components that require high consistency across millions of units. EV innovation depends on accurate thermal management and structural stability, both achievable through CNC.

Implants, surgical instruments, and micro-machined components demand extreme precision and biocompatible materials—areas where CNC excels. The medical industry relies heavily on CNC for ensuring patient safety.

As devices shrink, CNC Machining delivers thin-wall structures, heat sinks, molds, and precision housings with tight tolerances. Electronic systems benefit from CNC’s ability to produce detailed micro-features.

Combining CNC finishing with additive manufacturing creates stronger components with complex internal structures and smooth machined surfaces. This hybrid approach merges geometric freedom with precision finishing.

Future systems will integrate robotics, pallet automation, and AI scheduling to create self-managing production cells. These factories will eventually operate with minimal human oversight.

Super-alloys, carbon composites, engineered plastics, and function-graded materials will continue expanding CNC’s capabilities, enabling new industries and applications.

As precision and speed become competitive advantages, CNC Machining will be central to innovation in national defense, semiconductor fabrication, renewable energy, and global supply chains. Companies that embrace CNC will lead the manufacturing transformation.

CNC Machining is redefining precision, speed, and sustainability across modern manufacturing. AI control, adaptive machining, and digital twins are pushing factories toward a smarter future. Companies now treat CNC as a strategic advantage, not just a process. Suzhou Welden Intelligent Tech Co., Ltd. provides advanced CNC solutions that help teams achieve high accuracy, stable quality, and faster production.

A: CNC Machining increases accuracy, speed, and reliability, allowing companies to create precise CNC Parts at scale.

A: Multi-axis CNC Machining enables complex shapes and smoother surfaces, improving the quality of CNC Parts.

A: Aerospace, medical, and electronics sectors rely on CNC Parts for high precision and stable performance.

A: AI improves CNC Machining by optimizing toolpaths and predicting tool wear, helping factories produce consistent CNC Parts.

A: CNC Machining lowers costs by reducing scrap, preventing rework, and producing accurate CNC Parts on the first pass.

A: CNC Machining keeps material strength and tolerances consistent from prototype to final CNC Parts, enabling smooth scale-up.