T: +86-18962109320

E: james@sz-welden.com

E: james@sz-welden.com

55 Puxing Road, Linhu Town, Wuzhong District, Suzhou, Jiangsu Province, 215105, China

Views: 0 Author: Site Editor Publish Time: 2025-02-24 Origin: Site

The automotive industry is known for its rigorous requirements when it comes to component quality, precision, and performance. Every part, no matter how small, plays a critical role in the overall safety, functionality, and longevity of a vehicle. In this context, precision stamping has become a key manufacturing technique. Precision stamping parts allow for the production of high-quality, reliable, and cost-efficient components, making them indispensable in automotive manufacturing.

Precision stamping is a high-speed production method used to create complex shapes and features with tight tolerances. The technique ensures consistency and accuracy in every part produced, making it ideal for automotive applications where precision is paramount. The ability to produce components with minimal waste and faster production rates also aligns perfectly with the demands of the automotive sector, where time and cost are crucial factors.

One of the key areas where precision stamping is indispensable is in the production of automotive engine components. These parts, including valve spring retainers, timing gears, and crankshaft sprockets, need to meet strict performance criteria. High precision is essential to ensure that the parts fit together perfectly, function efficiently, and withstand extreme conditions.

Precision stamping is capable of producing these parts with the exact specifications needed, allowing for tighter tolerances and improved durability. With the automotive industry pushing for higher engine performance and efficiency, precision stamping ensures that every part contributes to these objectives.

In the automotive industry, safety is always a top priority. Components like airbag housings, seatbelt retractors, and crash-sensitive elements must be engineered to the highest standards. Any defect or inconsistency in these parts could jeopardize the safety of the vehicle occupants.

By utilizing precision stamping, manufacturers can produce safety-critical parts with remarkable accuracy and consistency. The precision of each stamped part guarantees that safety components function as intended, even in the most high-stress situations. For instance, airbag deployment systems rely on precisely formed components to ensure that the system functions at the exact moment needed to protect passengers.

Automotive body parts and structural components are crucial for the vehicle’s overall integrity and safety. These include parts like door frames, chassis brackets, and floor pans, which are subjected to immense stresses during operation. To ensure these components perform reliably over time, they must be manufactured with high precision.

Precision stamping excels in producing complex and strong parts, with the necessary strength to meet safety standards while being lightweight enough for modern automotive designs. With tight tolerances and precise material control, stamped parts contribute to the overall structural integrity and longevity of the vehicle, while also assisting in reducing the weight for improved fuel efficiency.

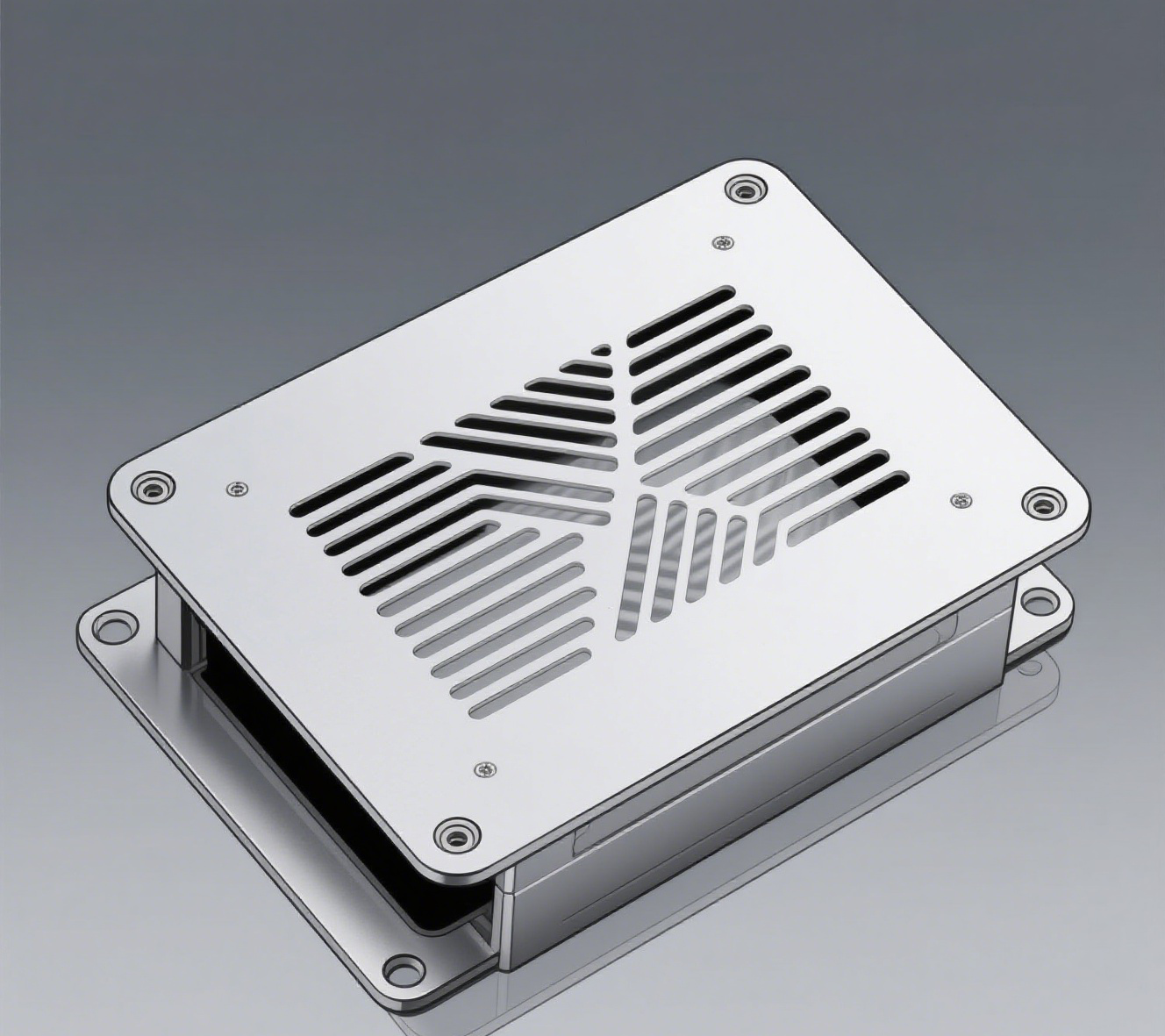

Modern vehicles are heavily reliant on advanced electronic systems, from engine control units (ECUs) to sensors, control modules, and electrical connectors. These systems require precise components that ensure proper connectivity and durability, as even minor defects can disrupt the system’s operation.

Precision stamping plays a vital role in producing these intricate parts. Components such as connectors, terminals, and casings are all manufactured using precision stamping, ensuring consistent quality and performance. With the automotive industry’s growing focus on electric vehicles (EVs) and autonomous driving technologies, precision stamping helps meet the evolving needs for highly reliable electronic systems.

Precision stamping has emerged as a crucial technology in the automotive industry, offering several key advantages that directly impact production quality and efficiency.

One of the main advantages of precision stamping is its ability to produce parts with extremely tight tolerances and uniformity. Whether it’s a small sensor housing or a larger structural part, precision stamping ensures that every component meets the exact specifications needed. This consistency in production is vital in the automotive industry, where even the smallest variations can result in assembly issues or performance failures.

The high precision of stamped parts also guarantees that components work seamlessly together, reducing the need for adjustments during assembly and minimizing the chances of malfunction. This, in turn, helps to improve the overall quality of the final vehicle.

Speed and cost-efficiency are critical in the automotive manufacturing process, and precision stamping excels in both of these areas. The high-speed nature of stamping allows for the rapid production of large volumes of parts, which is ideal for the mass production of automotive components. This fast production rate helps manufacturers meet tight deadlines and ensures that supply chains run smoothly.

Moreover, precision stamping reduces material waste, as the process is highly efficient in utilizing raw materials. With reduced waste and faster production, manufacturers can lower their costs and pass those savings on to consumers, making precision stamping an economically viable option for producing automotive parts at scale.

Another major benefit of precision stamping is its ability to create intricate and complex designs. Automotive parts often require detailed features, such as specific cutouts, holes, or embossing, that need to be precisely formed. Traditional manufacturing methods, such as casting or machining, may struggle to achieve these complex geometries efficiently.

With precision stamping, manufacturers can create highly complex parts with multiple features in a single pass. This capability is essential for producing parts that meet the ever-growing demands of automotive design, particularly with the push for more advanced vehicles like electric cars, which require specialized components.

Precision stamping not only supports the existing demands of automotive manufacturing but also drives innovation in the industry. As automotive designs become more advanced, the need for precise, high-performance components increases. Precision stamping is particularly well-suited to these evolving requirements.

As part of the ongoing drive toward sustainability and fuel efficiency, automakers are focused on reducing vehicle weight. Lighter vehicles require fewer materials, less fuel, and result in lower emissions, making them more environmentally friendly.

Precision stamping helps manufacturers produce lightweight but strong parts that contribute to overall weight reduction. For example, by using thinner materials and stamping parts to precise specifications, manufacturers can achieve the desired strength-to-weight ratio while keeping production costs low.

The rise of electric vehicles (EVs) has further elevated the importance of precision stamping. Many EV components, including battery packs, motor housings, and cooling systems, require exacting precision to meet performance and safety standards. Precision stamping offers the level of accuracy needed to produce these parts consistently, supporting the EV industry's growth.

Precision stamping plays a critical role in the automotive industry by ensuring that every part, from engine components to safety features and electronic systems, meets the highest standards of accuracy and reliability. Its advantages, including high precision, reduced production costs, and the ability to handle complex designs, make it an ideal solution for automotive manufacturing. As the automotive industry continues to innovate and evolve, precision stamping will remain a cornerstone of high-performance production.

At Welden—Smart and Precision Manufacturing, we understand the demands of the automotive industry and are proud to offer high-quality precision stamping parts that meet these rigorous standards. Our state-of-the-art precision stamping solutions ensure that every part we produce delivers exceptional performance, consistency, and cost-efficiency. To learn more about how our precision stamping parts can benefit your automotive manufacturing needs, visit our website at www.sz-welden.com and explore our range of products and services.